Have you ever watched sparks fly and metal melt, transforming into a seamless join? That’s the magic of welding, and robots are taking it to a whole new level. But how does one actually command these mechanical marvels in the world of welding? Let’s dive deep into the world of robot welding, understand its nuances, and equip you with the knowledge to become a true welding maestro.

Unveiling the World of Robot Welding

Imagine a world where welding, a task often associated with intense heat, blinding sparks, and demanding precision, becomes a symphony orchestrated by robotic arms. That’s precisely what robot welding offers. This advanced form of welding utilizes programmable robots to handle the welding torch and execute welds with remarkable accuracy and speed.

What Makes Robot Welding Tick?

At its core, robot welding involves three key components working in perfect harmony:

- The Robot: Think of this as the brawn of the operation. Typically, articulated robots with six axes of movement are employed, offering flexibility and reach within the welding workspace.

- The Welding Equipment: This is the heart of the process. It encompasses the power source, wire feeder (if applicable), and the welding torch itself, all precisely controlled to deliver consistent, high-quality welds.

- The Control System: This is the brain of the operation. A sophisticated computer system empowers operators to program welding paths, adjust parameters like welding current and voltage, and manage the overall welding process.

Why Robot Welding is Transforming Industries

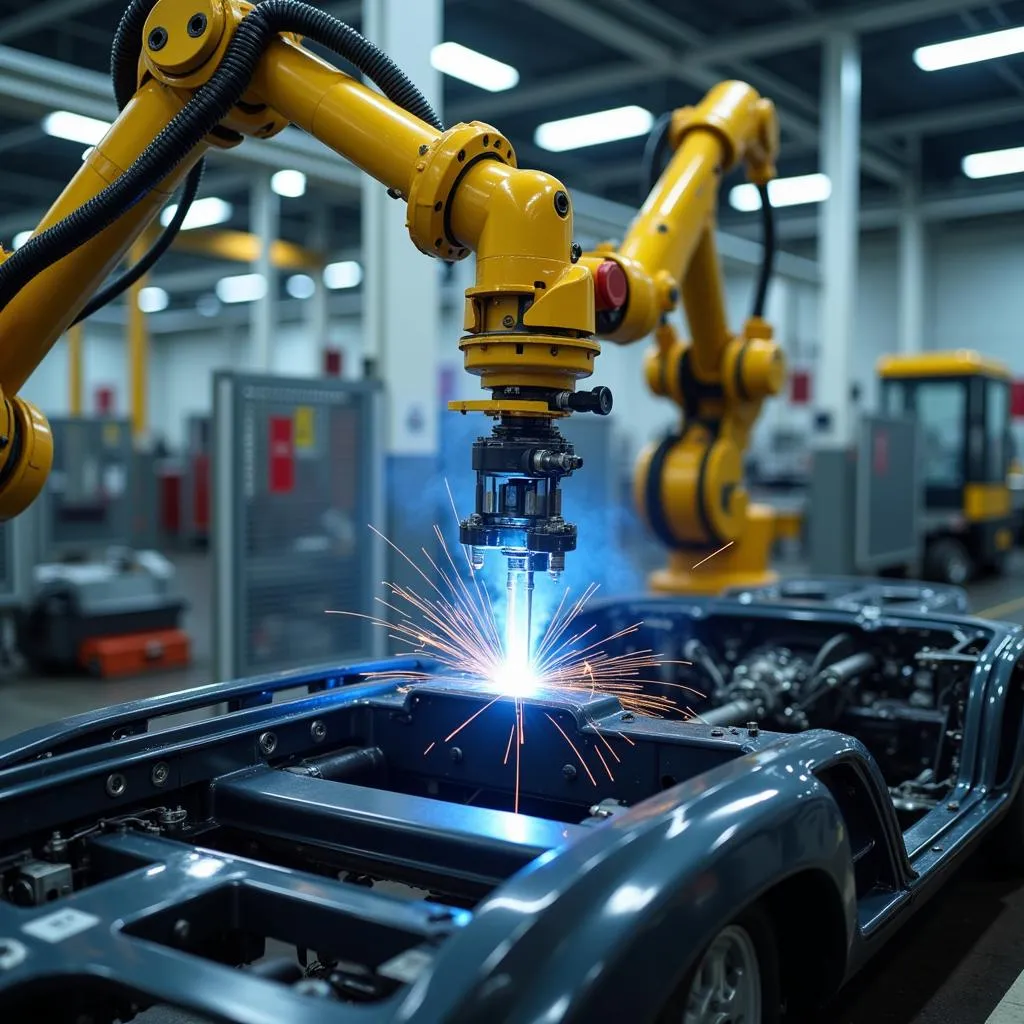

Robot welding in automotive manufacturing

Robot welding in automotive manufacturing

From automotive assembly lines to towering construction projects, robot welding is revolutionizing industries across the globe. Here’s why:

- Unmatched Precision and Repeatability: Robots thrive on consistency, delivering flawless welds time after time, minimizing errors, and reducing rework.

- Increased Productivity and Efficiency: Robots don’t take breaks or coffee breaks. They work tirelessly, significantly boosting output and shortening production cycles.

- Enhanced Safety: By keeping human operators at a safe distance from the intense heat and potential hazards of the welding arc, robot welding creates a safer working environment.

- Versatility and Adaptability: Robot welding systems can be easily reprogrammed and retooled to handle diverse welding tasks and product variations.

Demystifying Robot Welding Operation

Operating a welding robot might seem daunting at first, but it’s more approachable than you might think. Here’s a simplified breakdown:

1. Programming the Robot

- Offline Programming: Imagine choreographing the robot’s movements on a computer, much like designing a virtual dance. Specialized software allows operators to create detailed welding paths and define welding parameters before the robot even touches a workpiece.

- Teach Mode Programming: In this hands-on approach, operators use a teach pendant (a handheld control device) to physically guide the robot’s arm through the desired welding path. The robot remembers these movements and can repeat them accurately.

2. Setting Up the Workpiece

Accurate and consistent fixturing is crucial. The workpiece needs to be securely held in place, ensuring it doesn’t move during welding and that the robot can access the weld joints precisely.

3. Selecting Welding Parameters

Choosing the right welding parameters is akin to selecting the perfect ingredients for a recipe. Factors like welding current, voltage, wire feed speed (for MIG/MAG welding), and travel speed all influence the quality and penetration of the weld. These parameters are typically pre-set based on the material type and thickness, but fine-tuning might be necessary for optimal results.

4. Initiating and Monitoring the Welding Process

Once everything is set, the operator initiates the welding process. During welding, close monitoring is essential to ensure the robot follows the programmed path accurately, the weld pool looks good, and there are no unexpected issues. Modern robot welding systems often include sensors and cameras for real-time monitoring and quality control.

Essential Tips for Aspiring Robot Welding Operators

Ready to embark on your robot welding journey? Here are some valuable pointers from experienced Vietnamese welding professional, Nguyen Van Minh, author of “The Art of Robotic Welding Mastery”:

- Start with a Solid Foundation: A strong understanding of basic welding principles is paramount before diving into the world of robotics.

- Embrace Continuous Learning: The field of robotics is constantly evolving. Stay updated with the latest technologies and advancements through training courses, workshops, and industry publications.

- Don’t Be Afraid to Experiment: Within a controlled environment, don’t hesitate to experiment with different welding parameters and robot movements to gain hands-on experience and refine your skills.

Robot welding training center

Robot welding training center

Robot Welding: Shaping the Future, One Weld at a Time

Robot welding isn’t merely a technological advancement; it’s a paradigm shift in manufacturing. As automation continues its forward march, mastering robot welding opens doors to exciting career opportunities and contributes to building a more efficient and automated future.

Need help navigating the intricacies of Hanoi or seeking reliable transportation for your next adventure? Contact TRAVELCAR at 0372960696 or [email protected]. Our office is conveniently located at 260 Cầu Giấy, Hanoi. Let us be your trusted guide, whether you’re exploring the historic streets of Hoan Kiem District or venturing to the serene landscapes of Ba Vi. Our fleet of modern 16-seater, 29-seater, and 45-seater vehicles, along with our dedicated team, ensures a comfortable and memorable experience.