Setting up a servo delta robot can seem daunting, but with a clear understanding of the process and careful attention to detail, it becomes a manageable task. This guide provides a step-by-step approach to servo delta robot installation, covering everything from hardware assembly to software configuration.

Understanding the Servo Delta Robot

Before diving into the installation, it’s crucial to understand the unique characteristics of a servo delta robot. These robots, known for their speed and precision, utilize three arms connected to a fixed base, with the end-effector mounted on a triangular platform. This design allows for quick and accurate movements within a defined workspace. The “servo” aspect refers to the use of servo motors, which provide precise control over the robot’s movements.

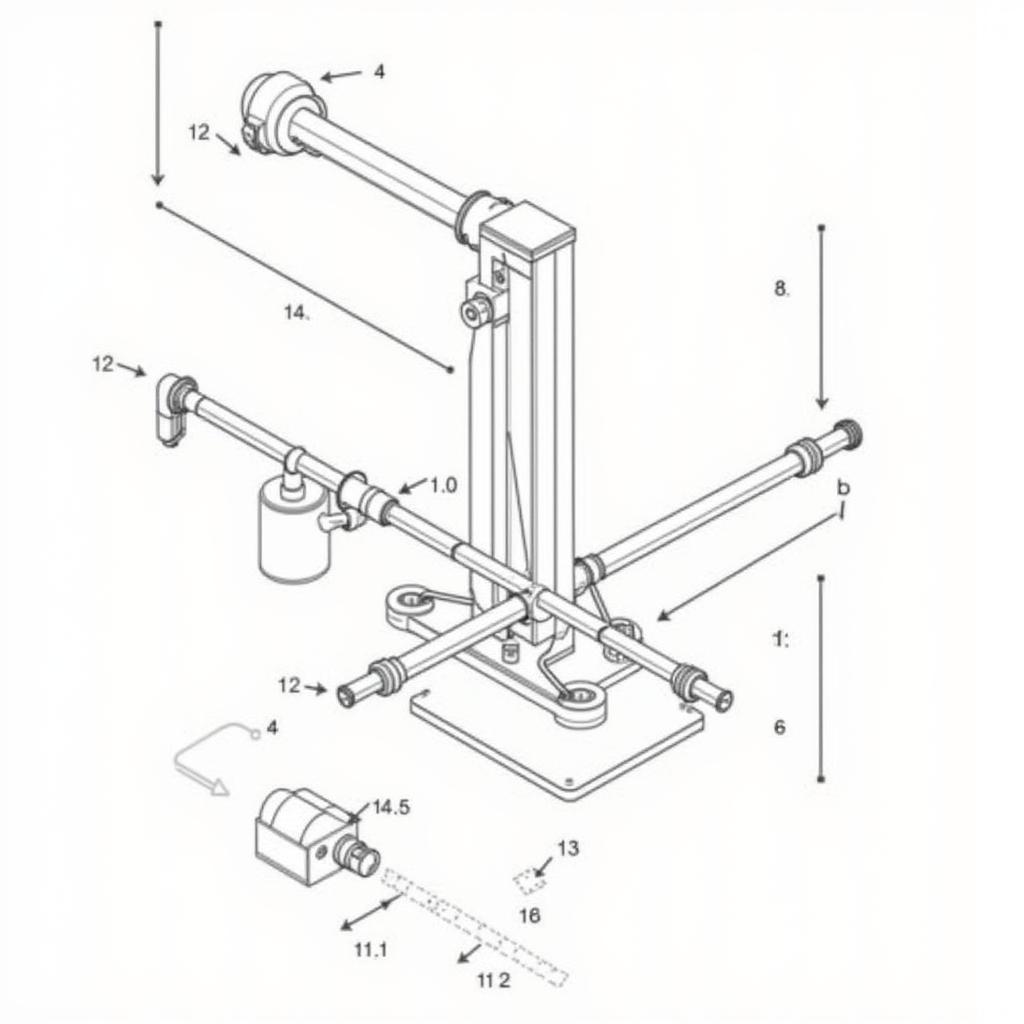

Servo Delta Robot Components Diagram

Servo Delta Robot Components Diagram

Hardware Assembly: Building Your Delta Robot

The first step in the installation process is assembling the physical robot. This involves connecting the arms to the base, mounting the motors, and attaching the end-effector. Ensure all connections are secure and properly aligned. Refer to the manufacturer’s instructions for specific details on your robot model, as variations exist.

Base and Arm Assembly

The base provides the foundation for the entire structure. Securely mount the base according to the manufacturer’s specifications. Next, attach the arms to the base, ensuring they move freely without obstruction. Proper alignment is critical for smooth operation.

Motor Installation and Wiring

Install the servo motors onto the designated mounts. Carefully connect the wiring, ensuring correct polarity and secure connections. Improper wiring can damage the motors or the control system.

Servo Motor Wiring for Delta Robot

Servo Motor Wiring for Delta Robot

End-Effector Attachment

The end-effector is the tool or gripper attached to the robot. Securely attach the end-effector to the triangular platform, ensuring proper alignment and stability.

Software Configuration: Bringing Your Robot to Life

Once the hardware is assembled, the next step is configuring the software. This involves setting up the control system, calibrating the robot, and programming the desired movements.

Control System Setup

The control system is the brain of the robot. Install the necessary software and drivers on your computer. Connect the control system to the robot and configure the communication parameters.

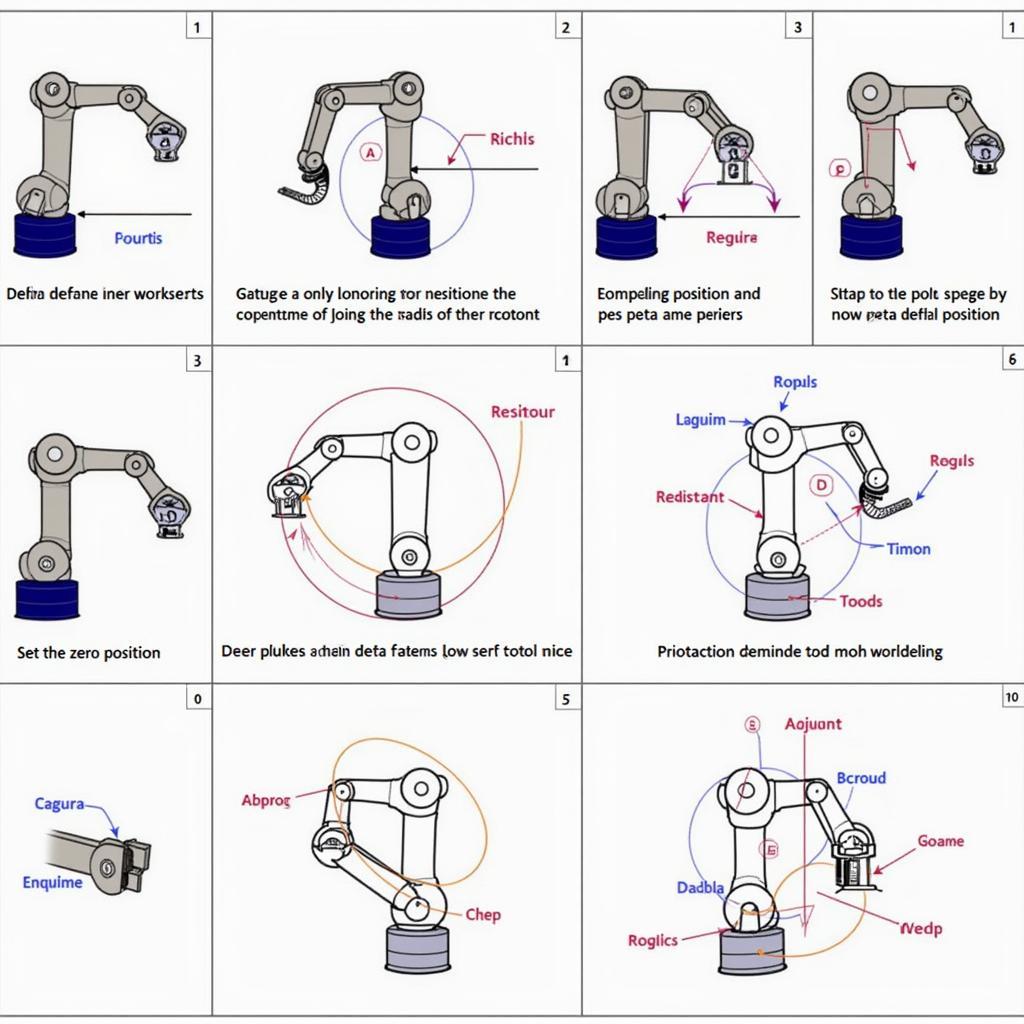

Calibration and Testing

Calibrate the robot to ensure accurate movement and positioning. This involves defining the robot’s workspace and setting the zero position. After calibration, test the robot’s movements to ensure everything is functioning correctly.

Delta Robot Calibration Steps

Delta Robot Calibration Steps

Troubleshooting Common Issues

During the installation process, you might encounter some challenges. Here are a few common issues and their solutions:

- Motor not responding: Check the wiring connections and power supply.

- Inaccurate movement: Recalibrate the robot and check for mechanical obstructions.

- Communication errors: Verify the communication settings and cable connections.

Conclusion

Successfully installing a servo delta robot requires careful planning and execution. By following the steps outlined in this guide, you can effectively assemble and configure your robot for optimal performance. Remember to consult the manufacturer’s instructions for specific details on your robot model. With patience and attention to detail, you can unlock the full potential of your servo delta robot.

FAQs

- What are the main advantages of using a servo delta robot? Servo delta robots offer high speed, precision, and repeatability, making them ideal for pick-and-place operations and other automated tasks.

- What type of maintenance is required for a servo delta robot? Regular lubrication, inspection of wiring and connections, and periodic recalibration are essential for maintaining optimal performance.

- How do I choose the right servo motor for my delta robot? Consider factors such as torque requirements, speed, and voltage compatibility when selecting servo motors.

- What software is commonly used to control delta robots? Various software packages are available, including open-source options and proprietary solutions from robot manufacturers.

- What are some common applications of delta robots? Delta robots are widely used in industries such as packaging, electronics assembly, and food processing.

- How do I program a delta robot for specific movements? Programming methods vary depending on the control system and software used. Many systems offer graphical interfaces and scripting languages for programming.

- Where can I find additional resources for learning about delta robots? Numerous online forums, tutorials, and educational resources are available for further learning and troubleshooting.

Need help with your Hanoi trip planning? Contact us at Phone Number: 0372960696, Email: TRAVELCAR[email protected] or visit us at 260 Cầu Giấy, Hanoi. We have a 24/7 customer support team ready to assist you.