Wire splicing, the art of joining two or more wires together, is a fundamental skill in various fields, from home repairs to complex electrical installations. Understanding the correct techniques for wire splicing ensures safe and reliable electrical connections, preventing potential hazards and ensuring the longevity of your electrical systems. This guide will equip you with the necessary knowledge and practical steps to perform wire splicing effectively.

Essential Wire Splicing Tools and Materials

Essential Wire Splicing Tools and Materials

Different Wire Splicing Techniques

Several methods can be employed for wire splicing, each with its own advantages and disadvantages. Choosing the right method depends on factors such as the type of wire, the environment, and the intended application.

Soldering

Soldering is a common technique that involves melting solder, a metal alloy, to create a permanent bond between wires. This method offers high conductivity and is ideal for applications requiring strong and reliable connections. However, soldering requires specialized equipment and practice to master.

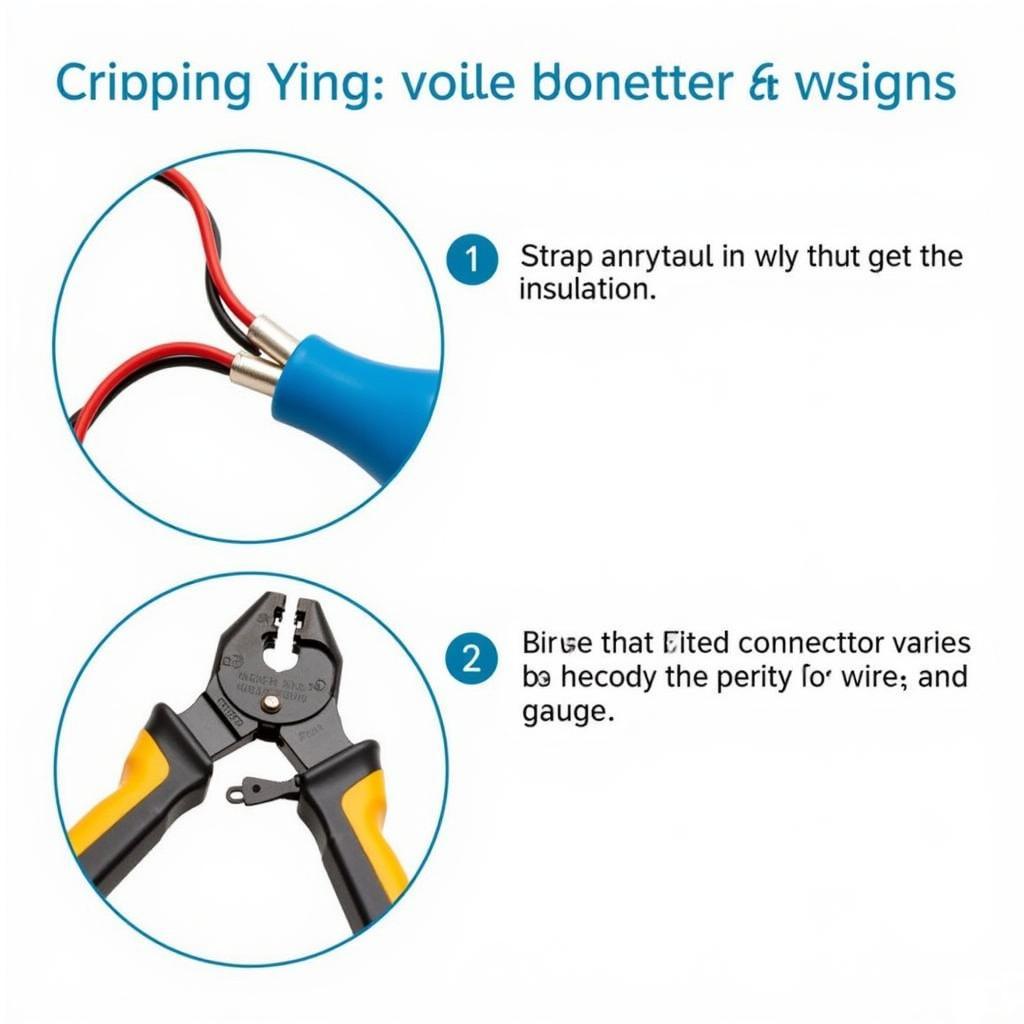

Crimping

Crimping utilizes special connectors and a crimping tool to join wires. This method is quick, easy, and requires minimal tools. It’s widely used in automotive and industrial applications due to its robustness and resistance to vibrations.

Wire Nuts

Wire nuts are plastic connectors that twist onto the stripped ends of wires, creating a secure connection. They are simple to use and ideal for low-voltage applications in residential settings. However, wire nuts are not as robust as soldering or crimping and are not suitable for high-vibration environments. If you’re unsure about a technique, perhaps try learning how to make cheese. hướng dẫn làm phô mai

Crimping Wire Connectors Step-by-Step Guide

Crimping Wire Connectors Step-by-Step Guide

Essential Tools and Materials for Wire Splicing

Before you begin any wire splicing project, it’s crucial to gather the necessary tools and materials. This includes:

- Wire Strippers: Used to remove the insulation from the ends of the wires.

- Crimping Tool: Essential for crimping connectors.

- Wire Connectors: Choose the appropriate type based on the application and wire gauge.

- Soldering Iron and Solder: For soldering connections.

- Electrical Tape: Used to insulate and protect the spliced connection.

- Multimeter: To test the continuity and ensure a proper connection.

Remember safety first. Always wear appropriate safety glasses and gloves while working with electrical wires. For a different kind of “how-to,” consider learning how to juggle a soccer ball. hướng dẫn tâng cầu

Step-by-Step Guide to Wire Splicing with Crimp Connectors

- Prepare the Wires: Strip the insulation from the ends of the wires, exposing the metal conductor.

- Select the Connector: Choose the appropriate size connector for the wire gauge.

- Insert the Wires: Insert the stripped ends of the wires into the connector.

- Crimp the Connector: Use the crimping tool to firmly crimp the connector onto the wires.

- Test the Connection: Use a multimeter to ensure a proper connection.

- Insulate the Connection: Cover the connection with electrical tape.

Testing Wire Splice with a Multimeter

Testing Wire Splice with a Multimeter

Expert Insights on Wire Splicing

“Proper wire splicing is crucial for any electrical system. It’s not just about connecting wires; it’s about creating a safe and reliable connection that can withstand the test of time,” says Robert Hernandez, a certified electrician with over 20 years of experience.

“Using the correct tools and techniques is essential. A poorly executed splice can lead to a variety of problems, including overheating, short circuits, and even fires,” adds Maria Rodriguez, an electrical engineer specializing in industrial applications.

Conclusion

Mastering the art of wire splicing is a valuable skill. By following the right procedures and using appropriate tools, you can ensure safe and reliable electrical connections, protecting your equipment and enhancing the longevity of your electrical systems. Remember, always prioritize safety and double-check your work. Understanding how to splice wires correctly is essential for any DIY enthusiast or professional electrician. Looking for something entirely different? Learn how to make a beautiful bow. hướng dẫn làm nơ bằng ruy băng vải

FAQs

- What is the best wire splicing technique? The best technique depends on the application. Soldering is ideal for permanent connections, crimping is best for high-vibration environments, and wire nuts are suitable for simple, low-voltage applications.

- How do I choose the right wire connector? Select a connector based on the wire gauge and the intended application.

- Is it necessary to use electrical tape after splicing wires? Yes, electrical tape provides insulation and protects the connection from moisture and damage.

- How do I test a wire splice? Use a multimeter to check the continuity of the connection.

- Can I splice different types of wires together? It’s generally not recommended to splice dissimilar metals together due to the risk of corrosion. If you need help with accounting, check this guide. hướng dẫn làm kế toán nội bộ

- What are the common mistakes to avoid when splicing wires? Common mistakes include stripping too much or too little insulation, using the wrong connector size, and not properly crimping or soldering the connection.

- What are the safety precautions to take when splicing wires? Always disconnect the power supply before working on any electrical wiring. Wear appropriate safety gear, such as gloves and safety glasses.

Need Help With Wire Splicing?

Contact us for assistance with all your transportation needs in Hanoi! Whether you need airport transfers, guided tours, or vehicle rentals, we are here to help. We offer a range of vehicles, including 16-seater, 29-seater, and 45-seater buses.

Call us at 0372960696, email us at TRAVELCAR[email protected], or visit our office at 260 Cau Giay, Hanoi. We have a 24/7 customer service team ready to assist you.