Rectangular hole jigs are essential tools for woodworking and metalworking, ensuring accurate and repeatable cuts. This guide will provide a comprehensive overview of designing and using rectangular hole jigs, covering everything from basic principles to advanced techniques.

Understanding Rectangular Hole Jigs

Rectangular hole jigs simplify the process of creating precise rectangular openings in various materials. They consist of a base plate with guide bushings that guide the cutting tool, such as a router or drill bit, along the desired path. This ensures consistency and prevents errors, especially when making multiple identical cuts. Why are they important? Imagine trying to freehand a perfect rectangle – challenging, right? A jig takes the guesswork out, guaranteeing clean, professional results.

Key Considerations in Jig Design

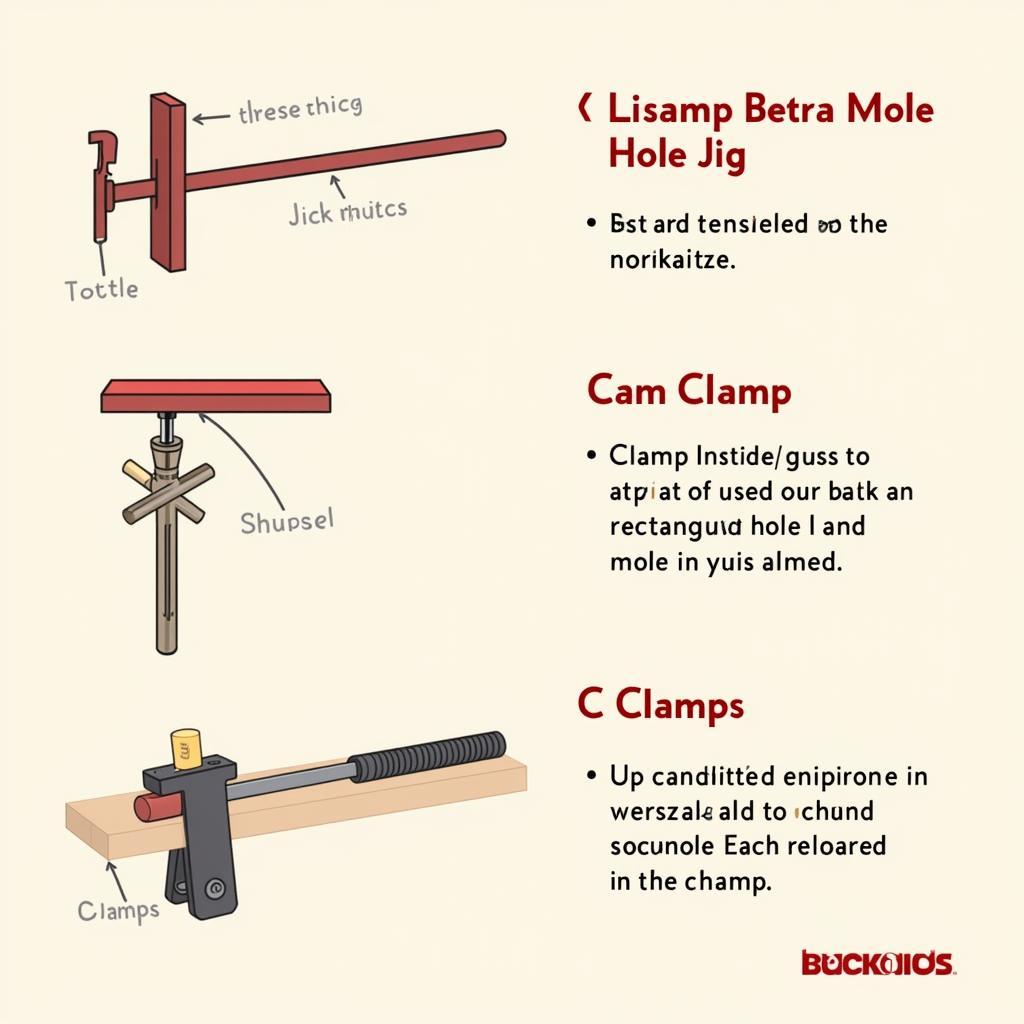

Several factors influence the design of a rectangular hole jig. The material thickness and the dimensions of the desired rectangular hole are primary considerations. The choice of guide bushings also plays a crucial role, as they determine the size and tolerance of the cut. Furthermore, the clamping mechanism needs to be robust enough to secure the jig firmly to the workpiece, preventing movement during the cutting process.  Choosing the Right Guide Bushings for Rectangular Hole Jigs

Choosing the Right Guide Bushings for Rectangular Hole Jigs

Material Selection for the Jig Base

The jig base should be made from a durable and stable material, such as hardwood plywood or acrylic. It should be thick enough to resist flexing and provide a solid foundation for the guide bushings. Stability is key here, as any wobble in the jig will translate to inaccuracies in the final cut.

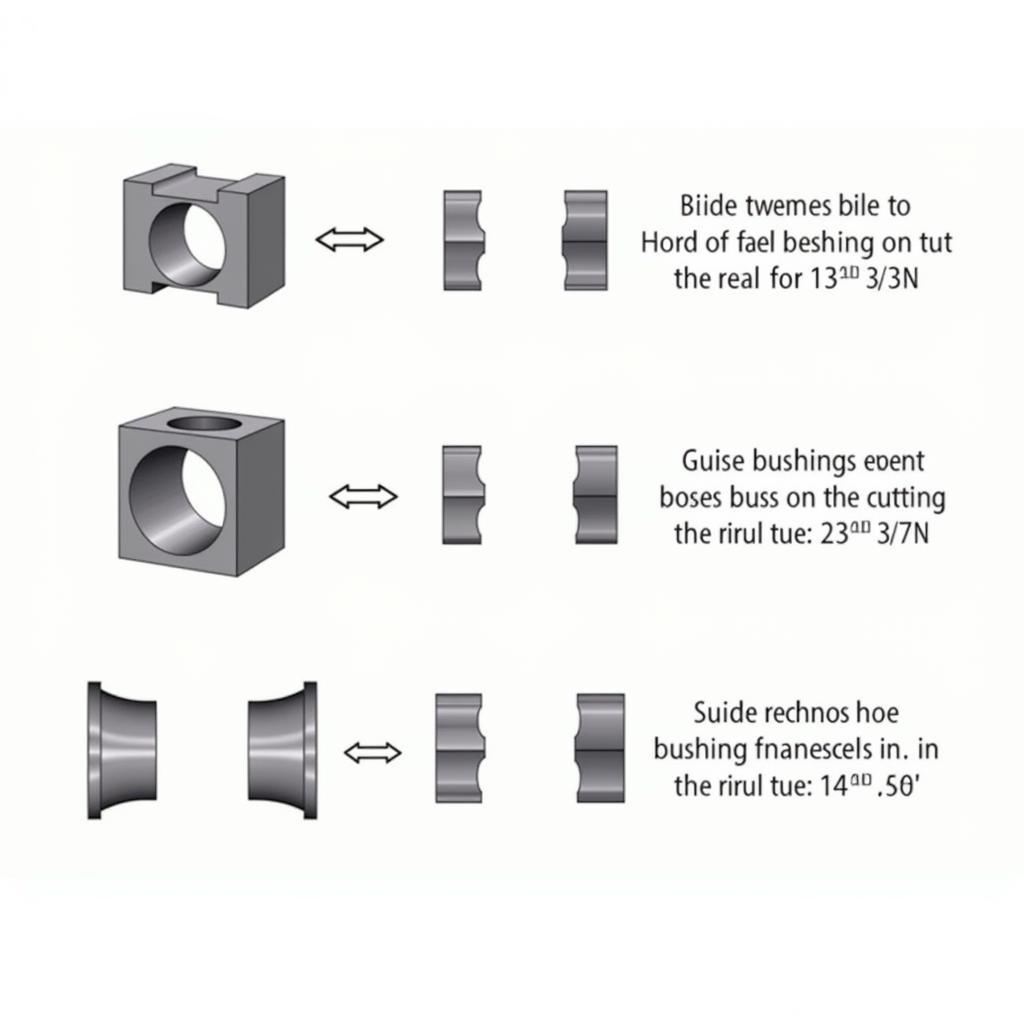

Determining the Dimensions and Placement of Guide Bushings

The placement of the guide bushings dictates the size and shape of the rectangular hole. Precise measurements and careful layout are crucial to achieve the desired outcome. The inner diameter of the bushings should match the diameter of the cutting tool.

Step-by-Step Guide to Building a Rectangular Hole Jig

- Determine the dimensions of the rectangular hole: Measure the length and width accurately.

- Select the appropriate guide bushings: Choose bushings that match your cutting tool diameter.

- Prepare the jig base: Cut the base material to size and ensure it’s flat and stable.

- Mark the bushing locations: Lay out the positions of the guide bushings based on the desired hole dimensions.

- Drill holes for the bushings: Use a drill press for accuracy and ensure the holes are the correct size for a snug fit.

- Install the guide bushings: Press-fit or secure the bushings into the drilled holes.

- Add a clamping mechanism: Incorporate a method to secure the jig firmly to the workpiece.

- Test the jig: Make a test cut on scrap material to verify the accuracy and functionality of the jig.

“A well-designed jig is an investment in quality and efficiency,” says John Carpenter, a seasoned woodworker with over 20 years of experience. “It saves time and ensures consistent results, especially for repetitive tasks.”

Clamping Mechanisms for Rectangular Hole Jigs

Clamping Mechanisms for Rectangular Hole Jigs

Maintaining and Storing Your Jig

Proper maintenance and storage will prolong the lifespan of your jig. Keep it clean and free of debris. Apply a protective coating, like wax or varnish, to prevent moisture damage. Store it in a dry and stable environment to prevent warping.

“Remember, accuracy is paramount,” advises Maria Sanchez, a renowned furniture maker. “Regularly check your jig for wear and tear and replace any damaged components to maintain precision.”

Conclusion

Designing and building a rectangular hole jig requires careful planning and execution. By following the guidelines and techniques outlined in this guide, you can create a jig that will help you produce accurate and consistent rectangular holes in various materials. Mastering this skill will undoubtedly enhance your woodworking and metalworking projects. Remember to choose appropriate materials, select the right guide bushings, and employ a robust clamping mechanism. With practice and attention to detail, you can achieve professional-quality results.

FAQs

- What type of wood is best for a jig base?

- Can I use a hand drill to install the bushings?

- How do I ensure the jig is square?

- What are the common mistakes to avoid when designing a jig?

- How often should I replace the guide bushings?

- Can I use this jig for metalworking?

- What are some alternative clamping methods?

For assistance, please contact us at Phone: 0372960696, Email: TRAVELCAR[email protected] or visit us at 260 Cau Giay, Hanoi. We have a 24/7 customer service team. Need help tying a perfect bow for your project? Check out our guide: hướng dẫn làm nơ bằng ruy băng vải.